In today’s fast-paced world of electronic innovation, flex PCB assembly has become a cornerstone of advanced product design. As devices become smaller, lighter, and more complex, traditional rigid printed circuit boards are no longer sufficient to meet the needs of modern technology. Flexible PCB assembly offers a smarter solution — combining superior electrical performance with unmatched mechanical adaptability.

Flex PCBs are designed to bend, twist, and fold into compact electronic housings without compromising signal integrity. This makes them ideal for next-generation applications in consumer electronics, automotive systems, medical devices, aerospace instruments, and wearable technology. By using flexible materials and innovative assembly processes, engineers can achieve lightweight, durable, and space-efficient circuit solutions that outperform conventional boards.

What is Flex PCB Assembly?

Flex PCB assembly refers to the process of mounting and soldering electronic components onto flexible circuit boards made from materials like polyimide or polyester. Unlike rigid boards, flexible PCBs can bend or fold to fit into tight enclosures, making them perfect for intricate electronic systems that require dynamic movement or compact design.

The assembly process involves several key stages — from material preparation and component placement to soldering, inspection, and final testing. Each step is carefully executed to ensure the flexible substrate retains its durability and electrical stability even under mechanical stress.

How Flex PCB Assembly Works

The flex PCB assembly process is similar to that of rigid PCBs but requires higher precision and careful handling. The following stages outline how a flex PCB is assembled:

-

Material Preparation

The process begins with selecting a flexible base material such as polyimide, known for its heat resistance, dimensional stability, and electrical insulation. The material is then cleaned and prepared for circuit patterning.

-

Circuit Imaging and Etching

The desired circuit design is transferred onto the flexible material using a photoresist layer and UV exposure. The unprotected copper areas are then etched away, leaving behind the circuit traces.

-

Drilling and Plating

Micro-vias or through-holes are drilled to create interconnections between layers. These are plated with copper to ensure strong electrical conductivity.

-

Solder Mask and Surface Finish

A flexible solder mask is applied to protect the copper traces from oxidation and damage. The surface finish, such as ENIG (Electroless Nickel Immersion Gold), enhances solderability and corrosion resistance.

-

Component Placement

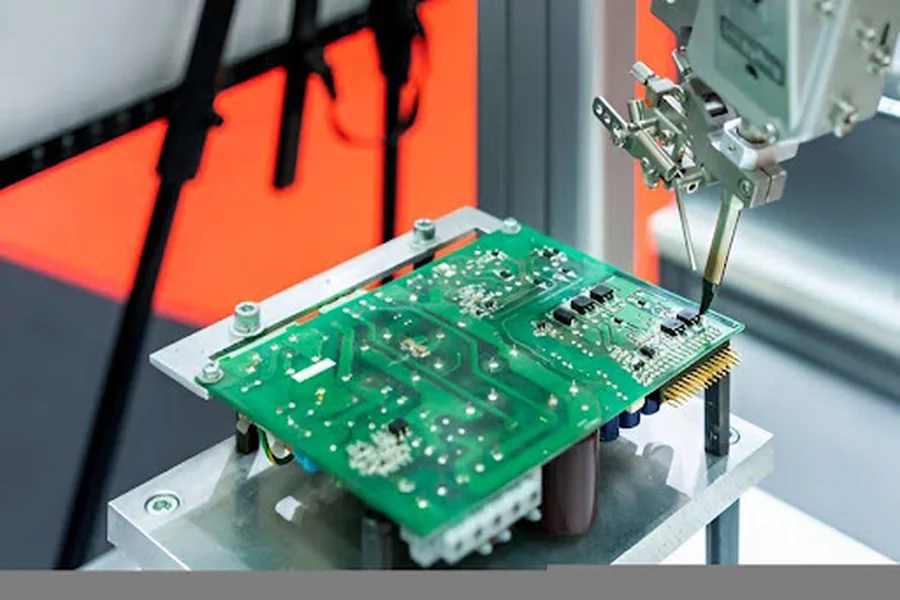

Surface Mount Technology (SMT) is widely used for component placement in flex PCB assembly. Automated pick-and-place machines ensure high precision, even when working with the delicate flexible substrate.

-

Reflow Soldering

The assembled flex PCB is passed through a controlled heating process where solder paste melts and forms strong electrical connections. Special temperature profiles are used to protect the flexible base material.

-

Inspection and Testing

Finally, advanced inspection methods like AOI (Automated Optical Inspection) and X-ray testing are used to detect defects such as solder bridges or misalignments. Electrical tests ensure the completed board meets performance standards before delivery.

Advantages of Flex PCB Assembly

Flex PCB assembly offers numerous advantages over traditional rigid board designs. These benefits make it a preferred choice for high-performance and space-constrained electronic systems.

-

Space and Weight Efficiency

Flex PCBs eliminate the need for connectors and cables between boards, significantly reducing size and weight. This is crucial in portable electronics, wearables, and compact automotive modules.

-

Enhanced Durability

The flexibility of these PCBs allows them to absorb vibrations and mechanical stress without breaking or delaminating. This makes them highly reliable in harsh environments and dynamic applications.

-

Superior Electrical Performance

By minimising interconnects, flex PCBs reduce signal interference and resistance, improving signal integrity and performance for high-speed electronic systems.

-

Design Versatility

Flex PCB assemblies can be folded or twisted into almost any shape, allowing designers to create innovative and compact layouts that were previously unachievable with rigid boards.

-

Cost Savings in Complex Systems

Although manufacturing costs may be higher initially, flex PCBs can reduce overall system costs by minimising wiring, connectors, and assembly time.

Applications of Flex PCB Assembly

Flex PCB assembly is transforming multiple industries through its adaptability and performance advantages.

Consumer Electronics

Smartphones, cameras, and laptops rely on flex PCBs for compact and lightweight connections between different modules. Their flexibility enables sleek product designs without sacrificing functionality.

Automotive Electronics

From infotainment systems to advanced sensors, flex PCBs are widely used in vehicles for their ability to withstand temperature variations and mechanical vibration.

Medical Devices

Medical equipment such as pacemakers, diagnostic tools, and hearing aids benefit from flexible circuit assemblies due to their small size and biocompatibility.

Aerospace and Defence

Flex PCBs provide superior reliability and weight reduction — essential factors in aerospace control systems, satellites, and radar applications.

Wearable Technology

In fitness trackers, smartwatches, and other wearable devices, flex PCB assembly allows seamless integration of circuits into compact, curved designs that move naturally with the user.

Challenges in Flex PCB Assembly

While the benefits of flex PCB assembly are numerous, certain challenges must be managed during production. The flexible substrate is more prone to tearing, deformation, or warping under high temperatures, so precision handling and strict process control are crucial. Additionally, engineers must account for bending radii, material thickness, and component placement to prevent stress-related failures.

Advanced manufacturers use laser cutting, specialised fixturing, and controlled reflow processes to ensure reliability and consistency in every assembly batch.

Why Flex PCB Assembly is the Future of Electronics

As electronic devices continue to demand higher functionality in smaller packages, flex PCB assembly stands out as the go-to solution. It offers not just mechanical flexibility, but also electrical precision, design efficiency, and reliability — all essential for next-generation electronic innovations.

The growing adoption of Internet of Things (IoT) devices, wearable tech, and smart systems ensures that the role of flexible PCB assembly will only expand in the years ahead.

Conclusion: Partner with Experts in Printed Circuit Board Assembly Services

In today’s competitive electronics industry, achieving optimal performance and reliability starts with choosing the right PCB technology and assembly partner. Whether you are developing compact medical devices, consumer gadgets, or automotive systems, flex PCB assembly provides the flexibility and performance your project needs.

To ensure superior quality and long-term dependability, it’s essential to work with professionals offering comprehensive printed circuit board assembly services. An experienced provider will deliver precision manufacturing, advanced materials, and reliable testing to bring your innovative designs to life with excellence and efficiency.