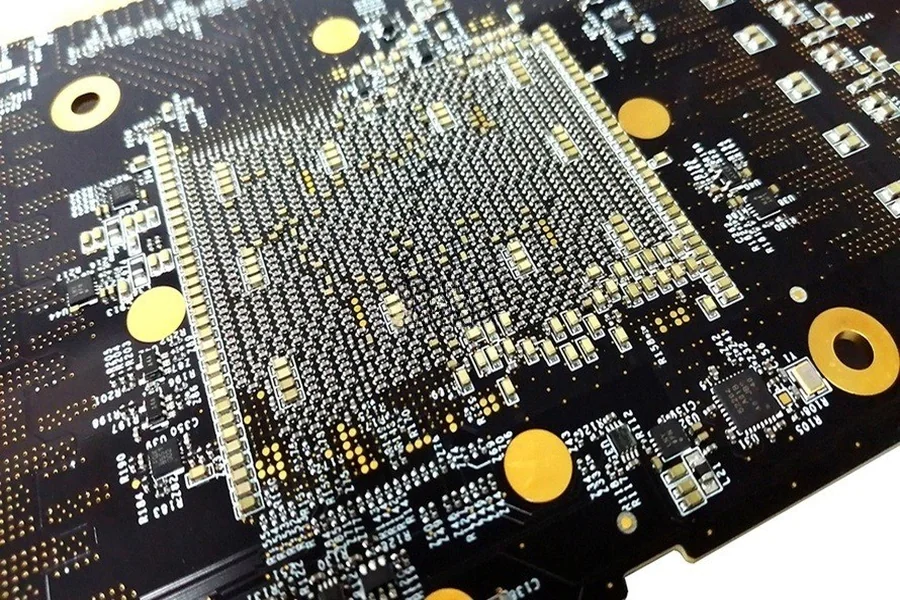

The High Speed Circuit Board is designed specifically to handle rapid signal transmissions without distortion or loss. As technology advances, electronic devices demand faster data transfer, higher frequencies, and improved reliability. Traditional PCBs often fall short under these conditions due to signal degradation and electromagnetic interference. High speed boards are engineered with advanced materials, layouts, and design techniques to maintain signal integrity and meet the needs of modern high-performance applications.

What is a High Speed Circuit Board?

A High-Speed Circuit Board is a PCB optimized for applications where signal frequency and transmission speed are critical. These boards typically operate above 50 MHz and are capable of supporting high-speed digital and RF designs. The choice of materials, dielectric constant, impedance control, and copper thickness are carefully considered to ensure minimal signal delay and distortion. Unlike standard PCBs, high speed boards prioritize low-loss materials and precise design rules to achieve consistent performance.

Characteristics of High Speed Circuit Board

High speed boards are distinguished by their ability to maintain signal integrity at elevated frequencies. They incorporate controlled impedance traces, low dielectric loss materials, and optimized stack-ups that reduce crosstalk and electromagnetic interference. Differential pair routing and careful via design are also crucial to minimize reflections and delays. These characteristics make high speed PCBs essential for reliable operation in advanced electronics.

Importance of High Speed Circuit Boards in Modern Technology

With the rise of high-frequency communication systems, 5G networks, data centers, and advanced computing, High Speed Circuit Boards are more important than ever. They ensure fast data transfer, improved bandwidth, and stable operation even under demanding conditions. This makes them indispensable for industries where precision and reliability are non-negotiable.

Applications of High Speed Circuit Boards

Telecommunications and Networking

High speed PCBs are essential in routers, switches, and servers that manage massive amounts of data at lightning-fast speeds.

Consumer Electronics

Laptops, gaming consoles, and smart devices rely on High Speed Circuit Boards to deliver smooth performance and quick response times.

Automotive Electronics

Modern vehicles equipped with advanced driver-assistance systems (ADAS) and infotainment platforms use high speed boards for real-time processing and communication.

Aerospace and Defense

In aerospace and military systems, high speed PCBs provide secure and rapid signal transmission for mission-critical equipment.

Advantages and Challenges of High Speed Circuit Boards

The advantages of high speed PCBs include improved signal quality, reduced latency, higher reliability, and compatibility with advanced technologies such as 5G and IoT. However, designing and manufacturing these boards require advanced expertise. Material selection, impedance control, and strict adherence to signal integrity principles increase complexity and production costs. Despite these challenges, the benefits far outweigh the drawbacks in high-performance applications.

Future of High Speed Circuit Boards

The future of High Speed Circuit Boards is closely connected with the growth of high-bandwidth applications, cloud computing, artificial intelligence, and next-generation communication systems. As industries continue to demand faster and more reliable devices, the need for advanced PCB technologies will only increase. Innovations in materials and design methodologies will further enhance performance and reduce limitations.

Conclusion

The High Speed Circuit Board plays a vital role in modern electronics by ensuring efficient and reliable signal transmission in high-frequency applications. From telecommunications to aerospace, these boards are at the core of innovation and performance. To achieve the best results, partnering with an experienced High Speed Circuit Board Manufacturer ensures optimized designs, high-quality materials, and precise fabrication tailored to advanced industry requirements.